Description

Wet wall cooling offers a very low cost and efficient system for greenhouse cooling and will operate really well when the humidity is not too high, reducing temperatures by 10C-15C degrees.

The theory with this system is to make the air inlet into the greenhouse through a porous material that can be saturated with water, similar to the “Coolgardie Safe”.

The air has to be drawn through the greenhouse in such volumes that due to the air speed through the wet wall the water is picked up and evaporates in the greenhouse to provide cooling.

Systems are installed with the fans at one end (or side) and the wet wall at the other, preferably with a maximum distance of 40 metres. As the system depends on drawing the air through the greenhouse, consideration should be given to making sure that air cannot be drawn in through vents, doors and cladding thus reducing the volume through the wet wall.

In order to calculate the air throughput required, we would take the cubic capacity of the greenhouse – width x length x average height (wall height + half of truss height).

eg. Greenhouse 40m x 20m x 4.5m = 3600 m3 (cubic metres). So, to change the air in the greenhouse once we have to pump in or draw out 3600 cubic metres of air.

We have found that the optimum ventilation level is about 50 air changes per hour for this type of system.

Total air movement per hour for the above greenhouse is 3600 x 50 = 180,000m3/hour.

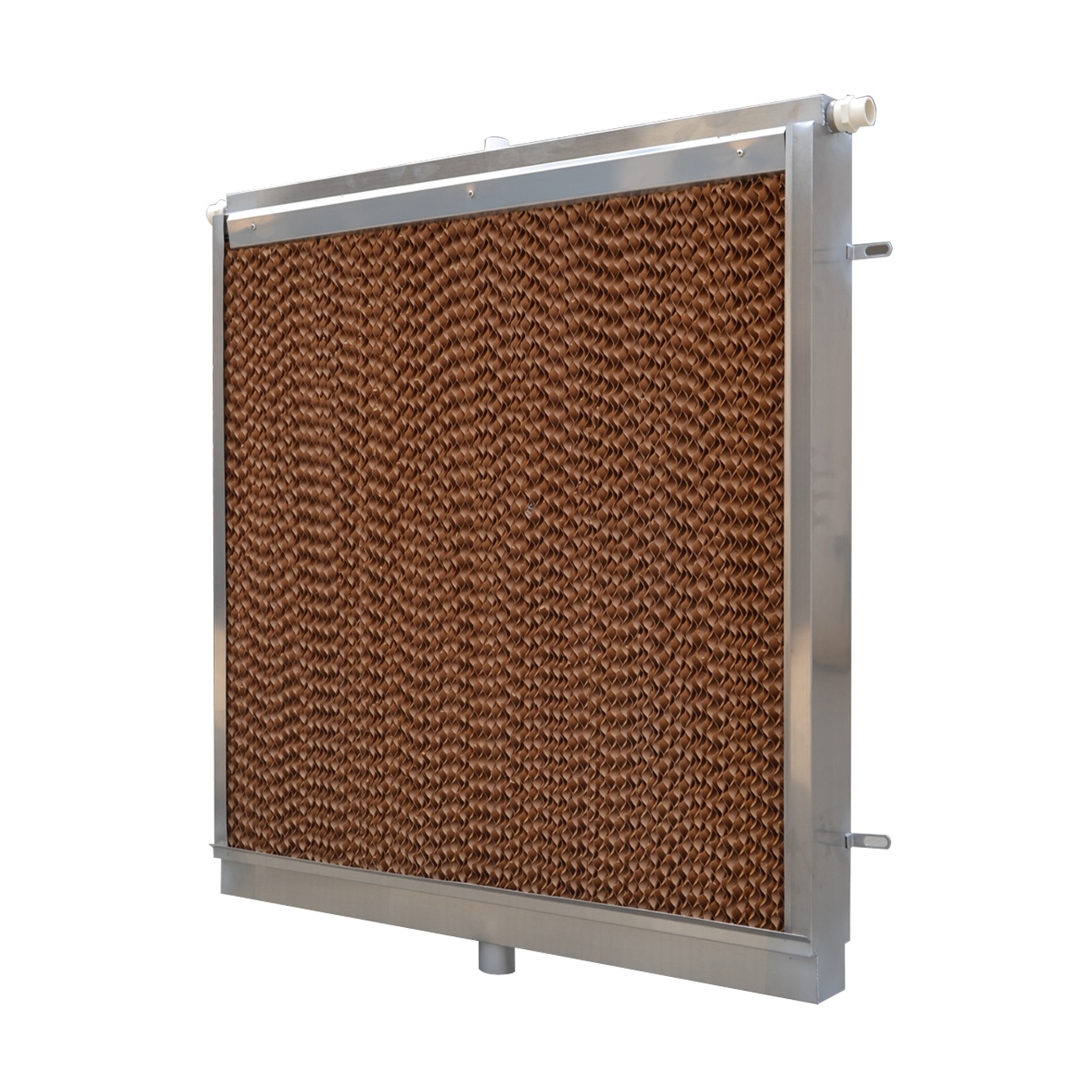

For the wet wall we use a 100mm thick cooling panel that will carry an adequate amount of water without creating too much resistance to air flow. The panel is framed with a perforated header pipe on top and a bottom drainage channel so that a continuous flow of water will keep all of the cooling panels saturated. The water is recirculated through a small tank that requires water treatment to make sure that there is no Legionnaires disease that is common to most evaporative systems.

The wet wall, greenhouse structure and contents create a resistance to the airflow so when we are working out the fan requirement we allow a reduction of 18% from the fan throughput rating.

eg. EF1 fan is rated at 44,500 m3/hour. Less 18% = 36,490 m3/hour.

EF3 fan is rated at 32,500 m3/hour. Less 18% = 26,650 m3/hour

180,000 = 4.9 EF1 fans(close enough for 5) 36,490 180,000 = 6.75 EF3 fans (close enough to 7)

The optimum air speed through the wet wall is 1.25 metres per second. Based on this, the 100mm pads will pass 4,743 m3 per hour.

180,000 = 37.95 square metres of wet wall. 4,743

Wet wall pads are 2m x 0.6m so we would fit either 32 in one row to form one large wall 19.2m long, or a number of smaller walls to add up to the same surface area (this can help the air distribution within the greenhouse).

We generally fit a 50 mesh insect net over the wet wall to filter the incoming air and reduce the dust input into the greenhouse. It is important that has 200% of the wet wall surface area. Evaporative Cooling Pads are fabricated from special cellulose material that has been treated with unique ingredients to achieve high cooling efficiency and degradation resistance.

Twin Skin Inflation Blower 140A

Twin Skin Inflation Blower 140A

Reviews

There are no reviews yet.